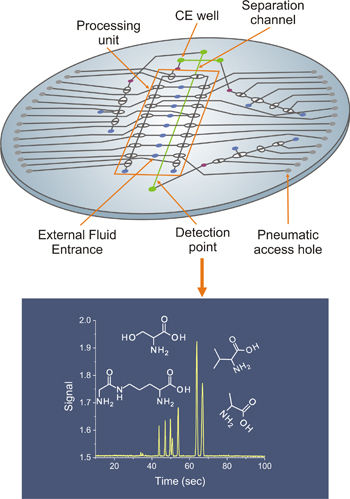

Bottom: Example of a separation of five amino acids using the microfluidic device (lab-on-a-chip).

The goal of planetary exploration missions is to learn as much as possible about alien environments. Learning about planetary bodies requires rovers, landers, and orbiters to take samples from these environments, process them, and send the data back to Earth. It is difficult enough to conduct science experiments in a laboratory where teams of researchers have access to cutting-edge technical tools. It is even more challenging to do this in space where researchers are millions of miles away from their equipment and can only patiently guide their experiment, step-by-step, through a delayed communications link.

To help meet this challenge, Peter Willis and California Institute of Technology Postdoctoral Fellow M. Fernanda Mora, technologists at the Jet Propulsion Laboratory in Pasadena, Calif., have recently developed a new "lab-on-a-chip" that is essentially an automated, miniature laboratory. This chip was designed and fabricated at JPL’s Microdevices Laboratory, and is the first chip known to autonomously perform all the sample processing, separation, and detection steps that a researcher would perform in the lab to search a sample for chemical markers and amino acids.

While lab-on-a-chip technology has been around since the 1990s, it has only recently been demonstrated to automatically carry out end-to-end experiments in a single device. "Before automating the analysis with this chip, all the sample handling and analyses were performed manually by the operator," says Mora. "This new technology enables the user to perform a whole analysis just by sending the right commands from the computer to the chip. Although we still need to manually place the sample and reagents on the device, we are currently working on different ways to introduce the sample in an automated fashion too."

The automated lab-on-a-chip is made of stacked glass wafers that are no larger in circumference than a DVD. Fluidic channels that are 50 x 20 microns are etched into the wafers with acid, making the chip ready to receive samples.

Extremely small liquid samples are delivered to the chip by an external sample delivery system that would be part of a rover or lander. Such a delivery system would be charged with identifying and gathering an appropriate sample and is not part of the lab-on-a-chip.

The lab-on-a-chip is able to start its work, once the sample arrives, by using a set of valves arranged in a fluidic circuit to move specific samples through the steps necessary for each experiment. Along the way, microchip capillary electrophoresis (μCE) with laser-induced fluorescence (LIF) detection is performed to identify specific chemical markers from the sample and report back to the researcher.

To set this automatic process in motion, all the researcher has to do is send a command to an in situ instrument, such as a lander, tell the lab-on-a-chip what experiment it is going to perform, and let it continually process samples as they become available. "The fact that we can remotely reprogram the system to perform different experiments is extremely useful for planetary missions to places such as Mars or Titan, where the samples encountered may be very different than anticipated," says Mora. "Having an adaptable, reprogrammable fluidic circuit is highly advantageous in these scenarios."

This new automation is what makes the lab-on-a-chip well suited for planetary missions where human beings are not present and where a sample return to Earth is not feasible. Additionally, the lab-on-a-chip consumes minimal amounts of each sample, requires low amounts of power to operate, is reprogrammable, and can be mass produced. This makes the lab-on-a-chip a highly attractive choice for planetary missions to places such as Mars, Titan, Enceladus or Europa.

Work to incorporate additional features into the lab-on-a-chip is already underway, such as adapting it to not just analyze fluid samples, but solid or gas samples as well. It also may come into everyday use as ideas for creating portable and cell-phone size chemical analysis hardware are already in the planning stages. "Although we are currently focusing on planetary exploration and astrobiology applications, this technology is invaluable here on Earth as well," says Willis. "Our vision is to create a handheld chemical analyzer that anyone could use. A user could download an app for analyzing whatever sample they were interested in. Our current work is a critical step in this process."

JPL is a division of the California Institute of Technology in Pasadena.

Contacts

Peter Willis

Phone: 818.393.6941

E-Mail: Peter.A.Willis@jpl.nasa.gov