Right: From left to right: Dr. Robert (Peter) Dillon, John-Paul Borgonia, and Dr. Douglas Hofmann showcasing a functionally graded metal insert made through additive manufacturing embedded in a carbon fiber panel.

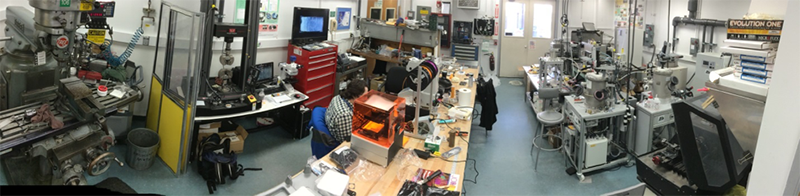

The JPL Metallurgy Facility is the primary research laboratory of the Materials Development and Manufacturing Technology Group. This lab focuses on early stage research and prototyping aimed at infusing new materials technology into NASA missions. The lab is one of the premier facilities in the country for work in the development of bulk metallic glasses and supports a number of research efforts, including advanced gears and actuators, mechanism, materials for robotics, carbon fiber laminates, spacecraft debris shielding, transparent ceramics, metal injection molding, alloy development, metal matrix composites, thermoplastic forming, gradient alloy design and 3D printing, metal additive manufacturing, among many others. Research in the lab primarily focuses on the creation of new bulk metallic glass alloys, manufacturing them into hardware and then testing that hardware compared to the state-of-the-art. As an example, the lab is able to create new alloys and then cast them into spur gears, test those gears in a gear rig to study their properties and then integrate them into actual gearboxes for environmental testing. The research group also does a substantial amount of metal additive manufacturing research and the lab supports the evaluation of those materials, which are produced by outside partners.

- Abdullah Aljabri - Group Supervisor

- Dr. Douglas C. Hofmann - Technologist

- Dr. Scott Roberts - Technologist

- John-Paul Borgonia - Technologist

- Dr. Robert P. Dillon - Technologist/Program Manager

- NASA Game Changing Technology Program for the development of metallic glass gears

- Air Force Office of Scientific Research for the development of metal matrix composites

- NASA flight program on the ISS for studies of sedimentation in metal matrix composites

- JPL/Caltech funding for the development of transparent sample return caches

- Strategic University Research Partnership (JPL/MIT) for hybrid metallic glass bearings