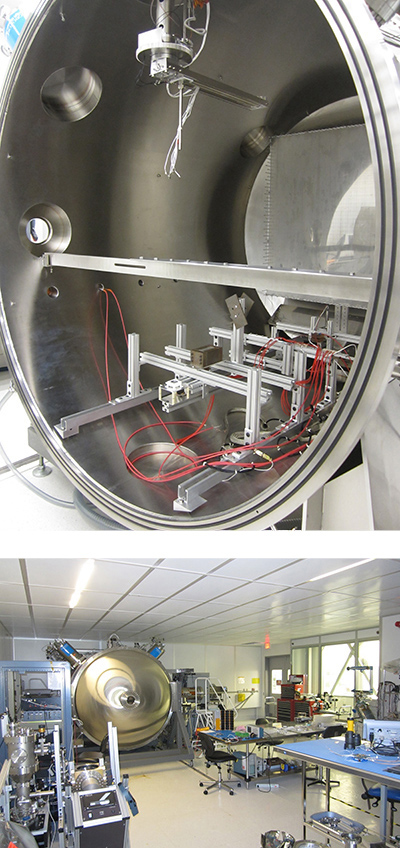

Bottom: The MPL at JPL

The MicroPropulsion Laboratory is a unique micropropulsion system cleaning, assembly, inspection, storage, and test facility in a 120 m2 class 10 cleanroom. Micropropulsion components or system performance, plumes, and spacecraft interaction characterizations can be conducted in this laboratory in a 2x2 m UHV chamber with a load-lock chamber (0.3 x 1m) or one of several smaller vacuum chambers. MPL has thruster diagnostics that include Faraday, an integrated temperature controlled quartz crystal microbalance and faraday probe, time-of-flight, emissive probes, beam targets and a micronewton thrust stand that have been implemented for electrospray thruster performance characterizations. It has 2-axis small and very large probe positioning systems. The micronewton thrust stand is unique because it has a vertical orientation with ~10 micronewton resolution. MPL also has a nitrogen purge box for thruster hardware storage.

The following activities have been performed at the MPL:

- Colloid thruster and Field Emission Electric Propulsion (FEEP) thrusters have been cleaned, assembled, and tested in the MPL. Microfluidic propellant flow studies have been conducted in this laboratory.

- Electrospray thruster assembly, component performance, and lifetime testing with Busek, Inc. was conducted in MPL with their Colloid MicroNewton Thruster (CMNT) for the LISA Pathfinder and potential follow-on LISA missions.

- Electrospray thruster ionic liquid, liquid metal propellant, and feed system testing have been conducted for electrospray thruster feed system design, operating procedure development, and propellant performance capability characterization.

- The JPL Microfluidic Electrospray Propulsion (MEP) technology has been assembled at the MPL, and this assembly and components were tested for performance and lifetime characteristics.

- Both MEP thruster and Busek CMNT power processing units have been tested in MPL to develop control algorithms for ground and flight operations.